AMPAK Company, Inc. has established supplier relationships with many of the world's leading manufacturers from India, China, and the Pacific Rim.

LAKESHORE TECHNOLOGIES:

In addition to global sourcing of high-quality ingredients, AMPAK Company, Inc. can further process these ingredients and add more value for customers through our sister company, Lakeshore Technologies, an FDA registered and ISO 22000 certified facility.

Custom Process and Equipment

Take advantage of our experience and abilities to design custom processes and equipment. Whether it involves materials processing, packaging or special handling, we can design a program around your needs, schedules and specifications.

Diffusion and Tumble Blending

Lakeshore Technologies uses diffusion blenders to achieve uniformity. With diffusion blending, different particle sizes and densities within certain bounds can be accommodated without the separation of smaller particles due to aeration or air flow through the product. Tumble blenders offer the best blend, typically achieving 1% – 2% variations and at times even significantly better than that. When a precise blend is required or some of the individual ingredients in the mix constitute less than 5% – 10% of the total, this is the technology that is chosen.

This system can accommodate any combination of raw material and/or final packaging containers.

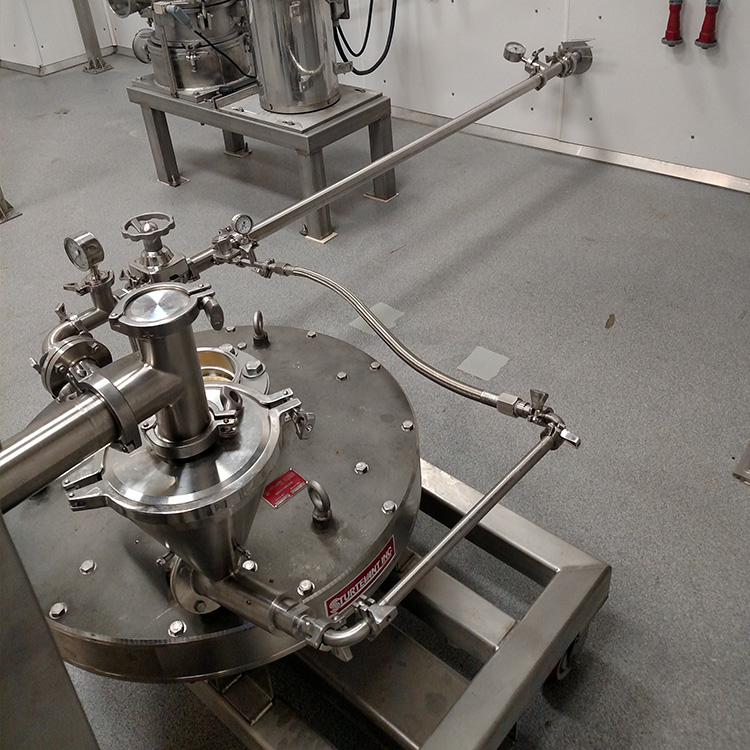

Jet Milling

The jet milling system has the capability to reduce products down to as low as 0.5 microns in size. At this low micron size, the material’s surface area is greatly increased, creating better properties for suspensions, dispersion and absorption. Other benefits include tighter particle size distribution and better uniformity while maintaining a spherical particle shape. Some of the key attributes of the Lakeshore Technologies milling system are:

• Low product loss

• Ability to process heat-sensitive products

• Sanitary design

• No lubrication or media contamination

• Low or no product heat build-up

• Ability to process up to 1000 lbs. (454 kgs) an hour

Metal Detection

Our metal detection system will accurately detect and remove metal contaminates with no impact to the raw material. It is able to detect fragments as small as 0.4 mm, non-ferrous; 0.4 mm ferrous; and 0.6 mm stainless steel. Our metal detecting system can accommodate any combination of raw materials and/or final packaging containers.

Micronizing – Milling

Because of its ability to process a wide range of products and particle sizes, the Lakeshore Technologies air classifier mill is the “go-to” for most of our customers’ size reduction needs. The result of this process is a product that is uniform, uncompromised, and with a tight particle size distribution. The air classifier mill’s ability to grind heat sensitive products makes it the number one system for size reduction.

This system can accommodate any combination of raw materials and/or final packaging containers.

Repacking

Lakeshore Technologies has the ability to repackage your products into more desirable container sizes at an affordable price. Available repackaging weights from 20kg-1200kg.